Complying with the FMSA Preventive Controls for Human Food Rule

Author: Girish M. Ganjyal

Published: 2021

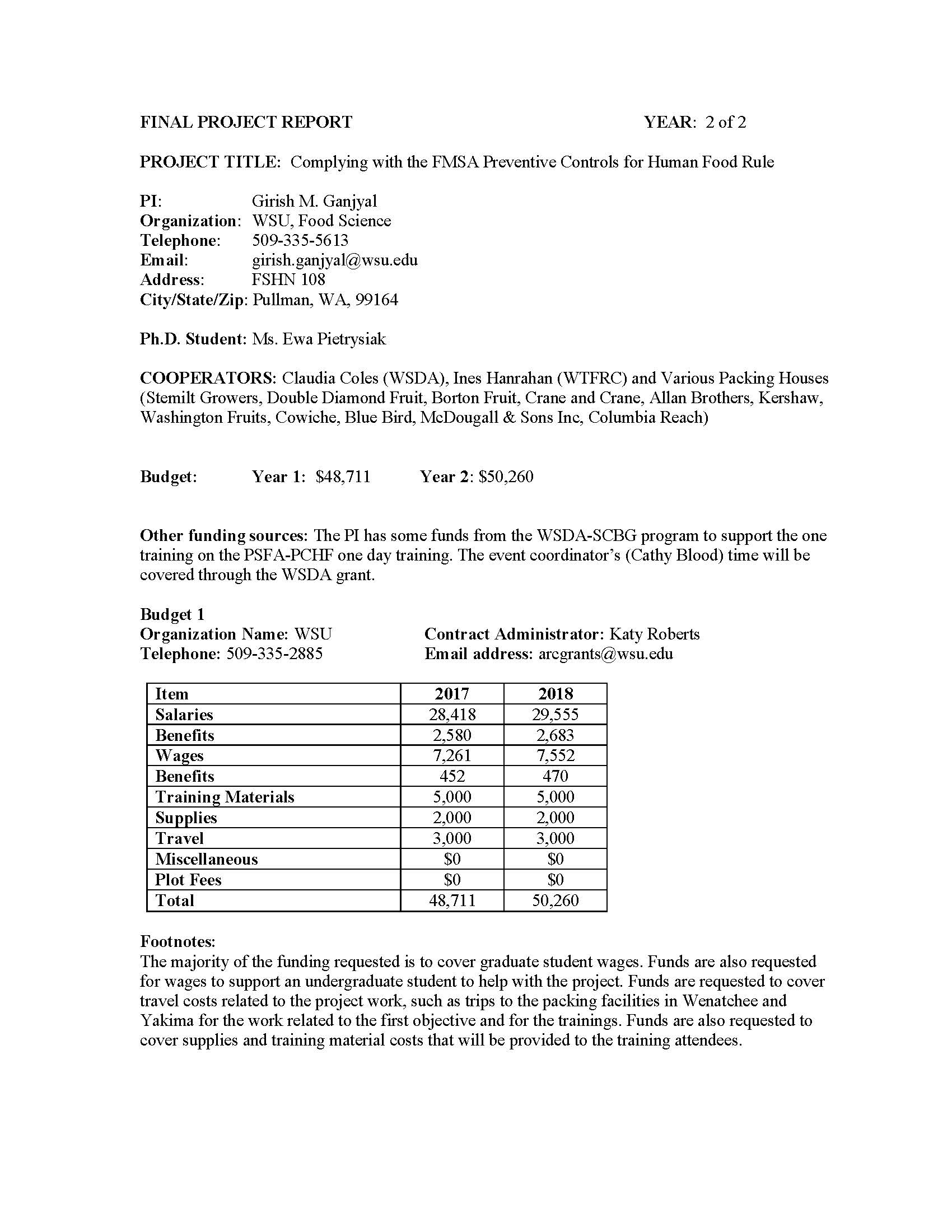

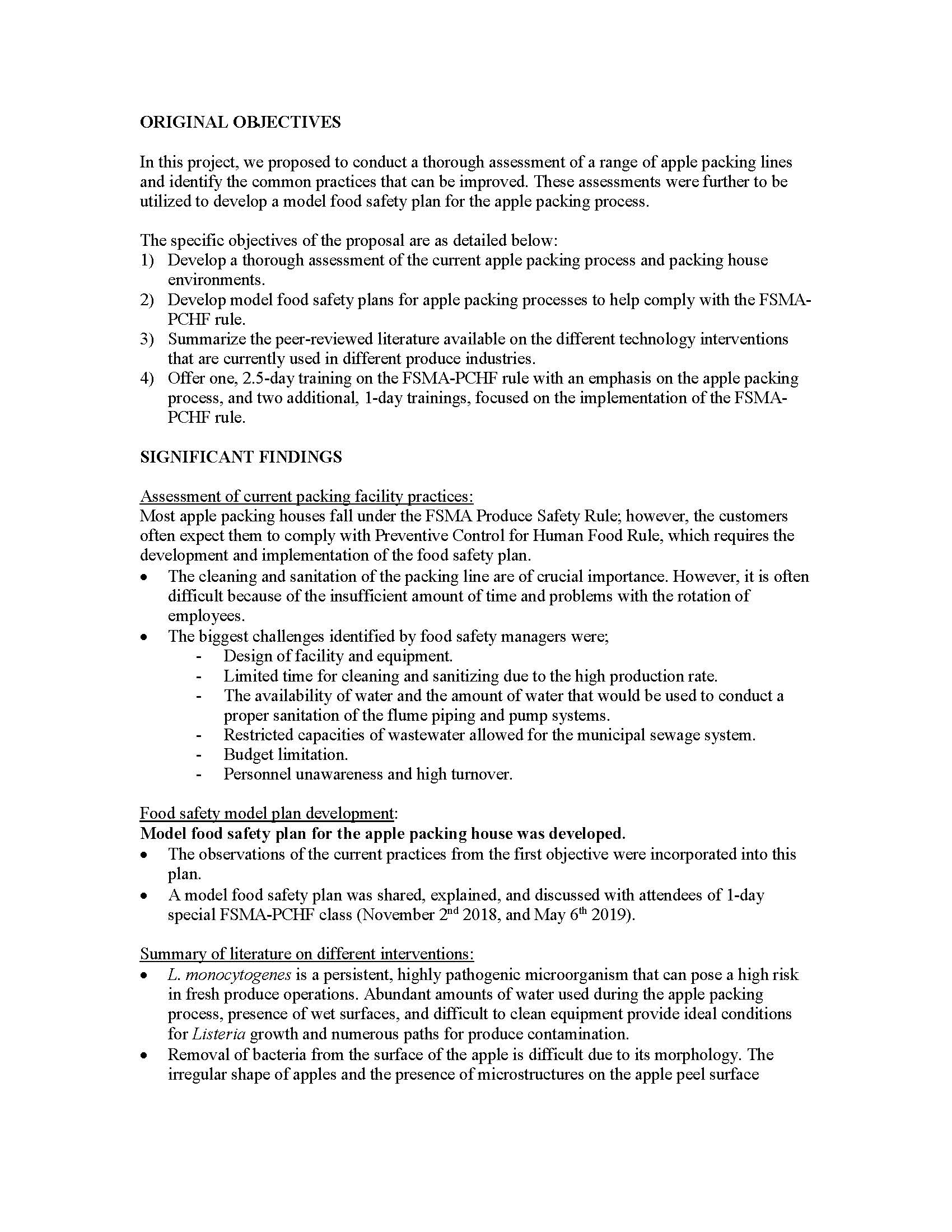

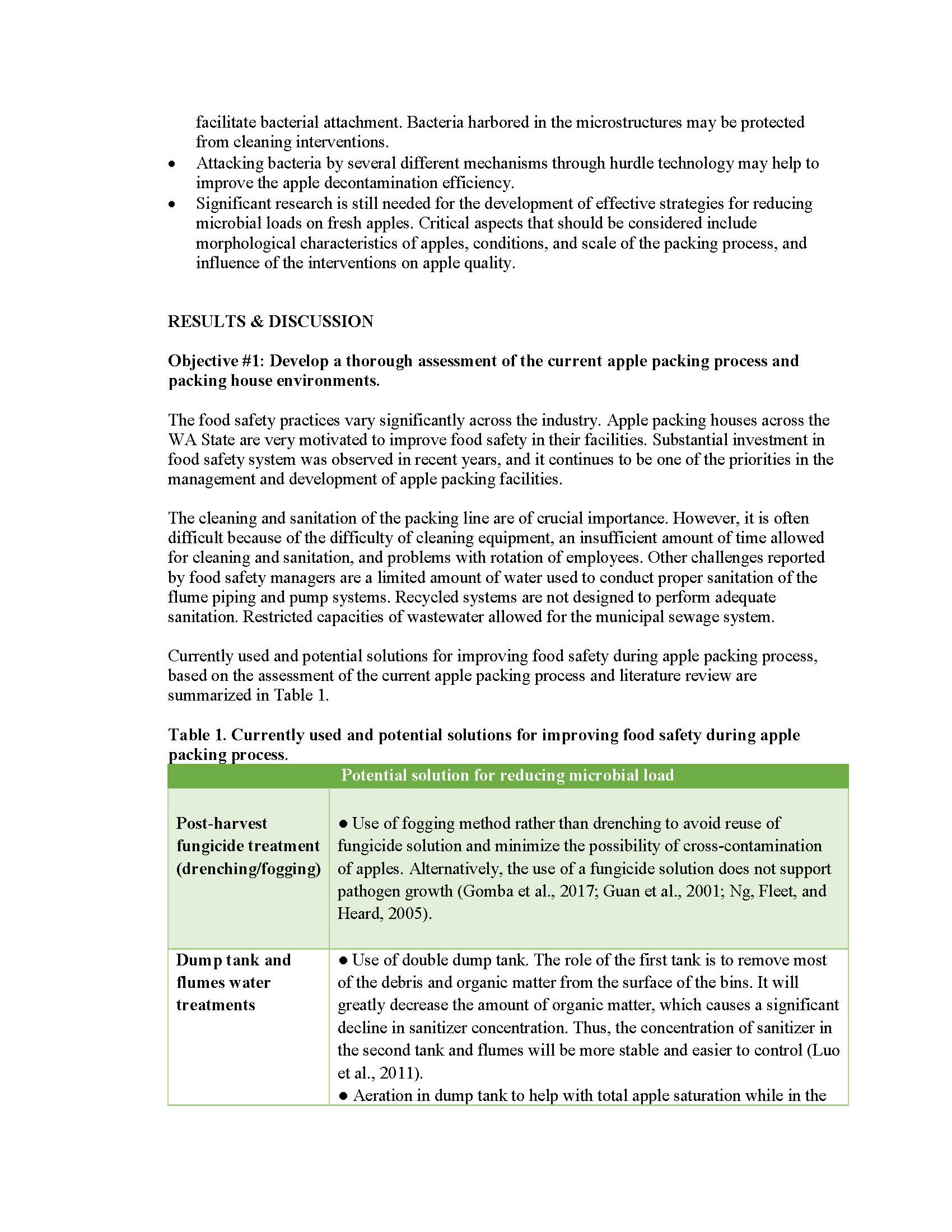

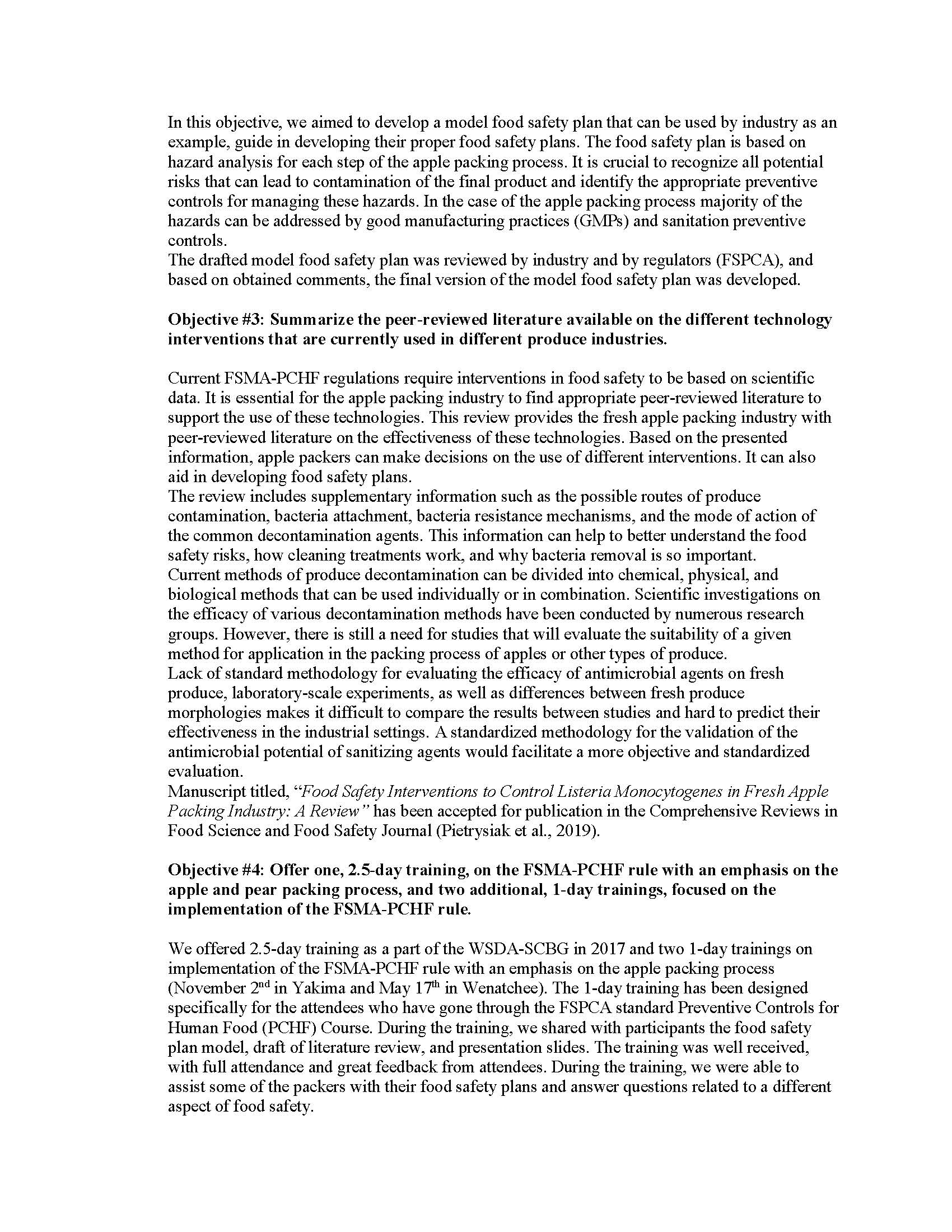

Summary: The overall goal of this project was to increase the effectiveness of the food safety systems and help apple packing houses in complying with new FSMA-PCHF regulations. Based on (i) visits to various facilities; (ii) survey outcomes; (iii) scientific literature review; (iv) comments from industry and FSPCA, the food safety plan model was finalized. The biggest challenges identified by food safety specialists are difficult (or impossible) to clean equipment, very limited time for cleaning and sanitizing, use and treatment of water, budget limitation, and personnel unawareness, and high turnover due to high production rate. Currently used and potential solutions for improving food safety during the apple packing process, based on the assessment of the current apple packing process and literature review were summarized. Current methods of produce decontamination were reviewed and presented in a manuscript titled, “Food Safety Interventions to Control Listeria Monocytogenes in Fresh Apple Packing Industry: A Review” (is available online @ https://doi.org/10.1111/1541-4337.12496). Additionally, this review contains supplementary information such as the possible routes of produce contamination, bacteria attachment, bacteria resistance mechanisms, and the mode of action of the common decontamination agents. This information can help to better understand the food safety risks, how cleaning treatments work, and why bacteria removal is so important. Scientific investigations on the efficacy of various decontamination methods have been conducted by numerous research groups. However, there is still a need for studies that will evaluate the suitability of a given method for application in the packing process of apples or other types of produce.

Keywords: