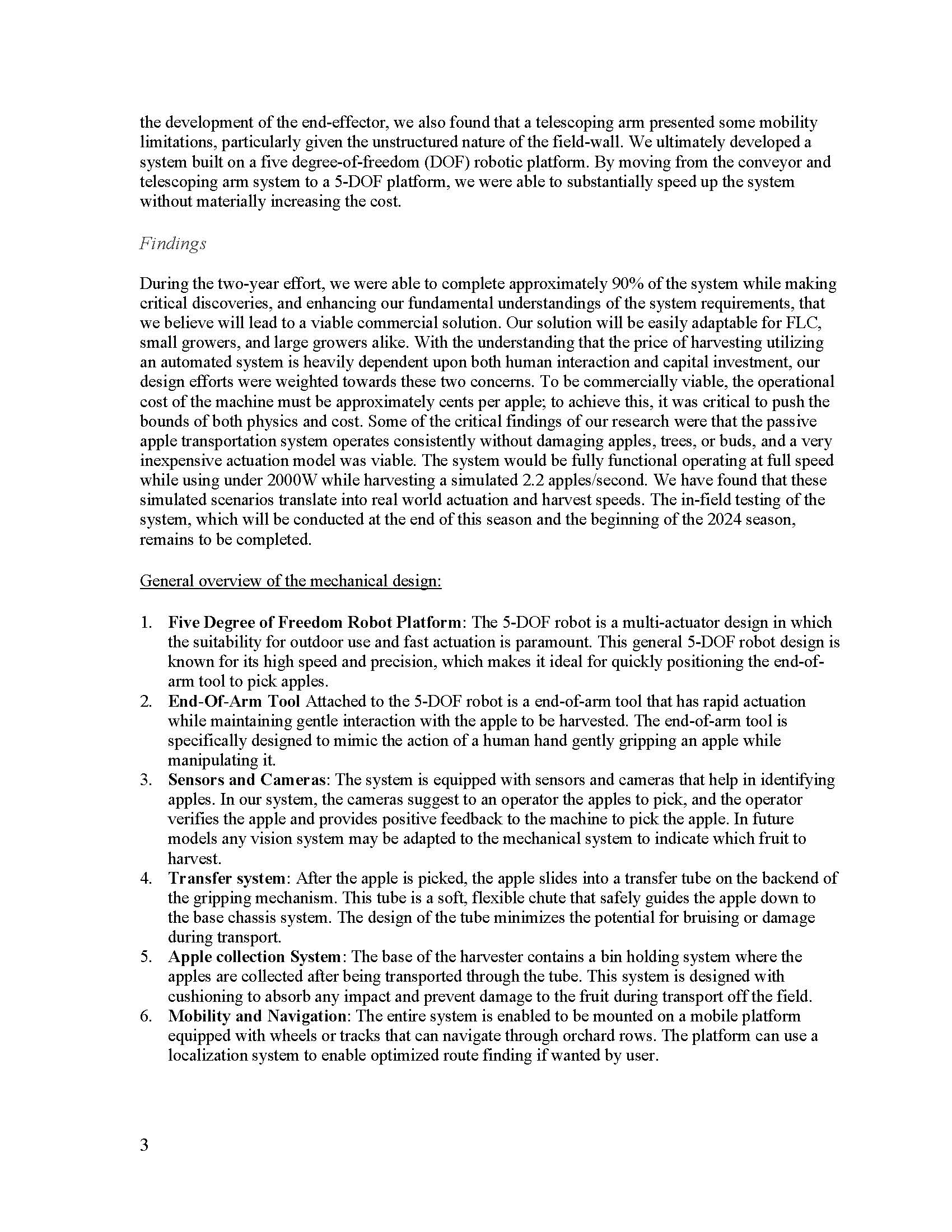

Apple Harvest End Effector and Apple Transport System

Author: Dominic Milano

Published: 2024

Summary: Keywords: Automation, Apples, Harvesting, Low-Cost, Reliability. Milano Technical Group was provided funding to research and develop a robotic apple harvesting system, including an end effector and apple transport system, to reduce in-field harvest operations and labor costs. After a substantial discovery process and many iterations, we determined that a potential multi-objective solution system consists of a five-degree of freedom system with a padded gripping mechanism and actuating arm, which allows for freedom of fast movement in multiple dimensions. The system is mobile base agnostic and will be tested using an Amiga from farm_ng. Where feasible, the system was built with off-the-shelf and low-cost parts to minimize build and maintenance costs. We estimate that each arm can retrieve an apple every 3 to 4 seconds and actuate between 1 and 2 million times between major maintenance periods.

Keywords: