Low-Cost, Reliable Soft Arm for Robotic Tree Fruit Operation Phase II

Author: Ming Luo

Published: 2025

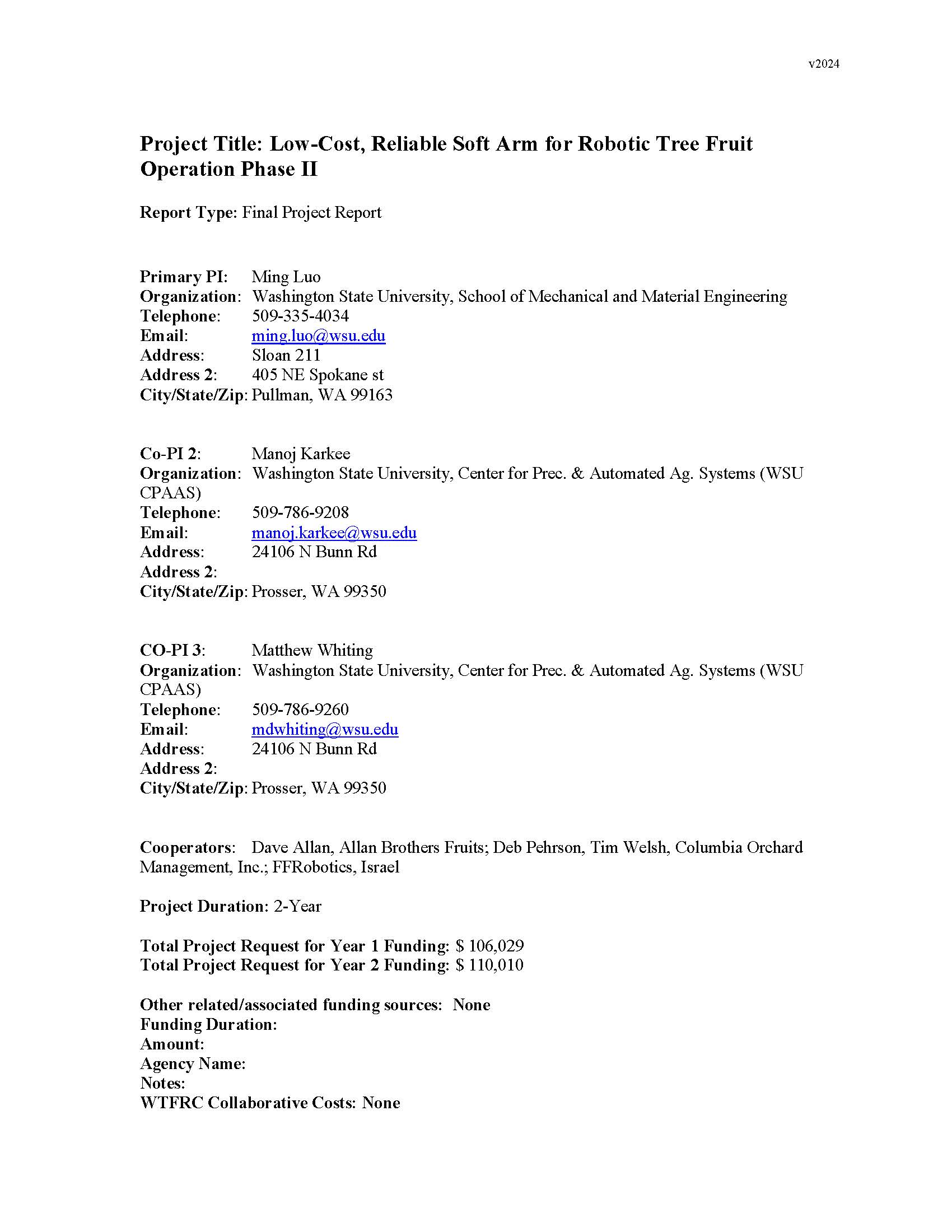

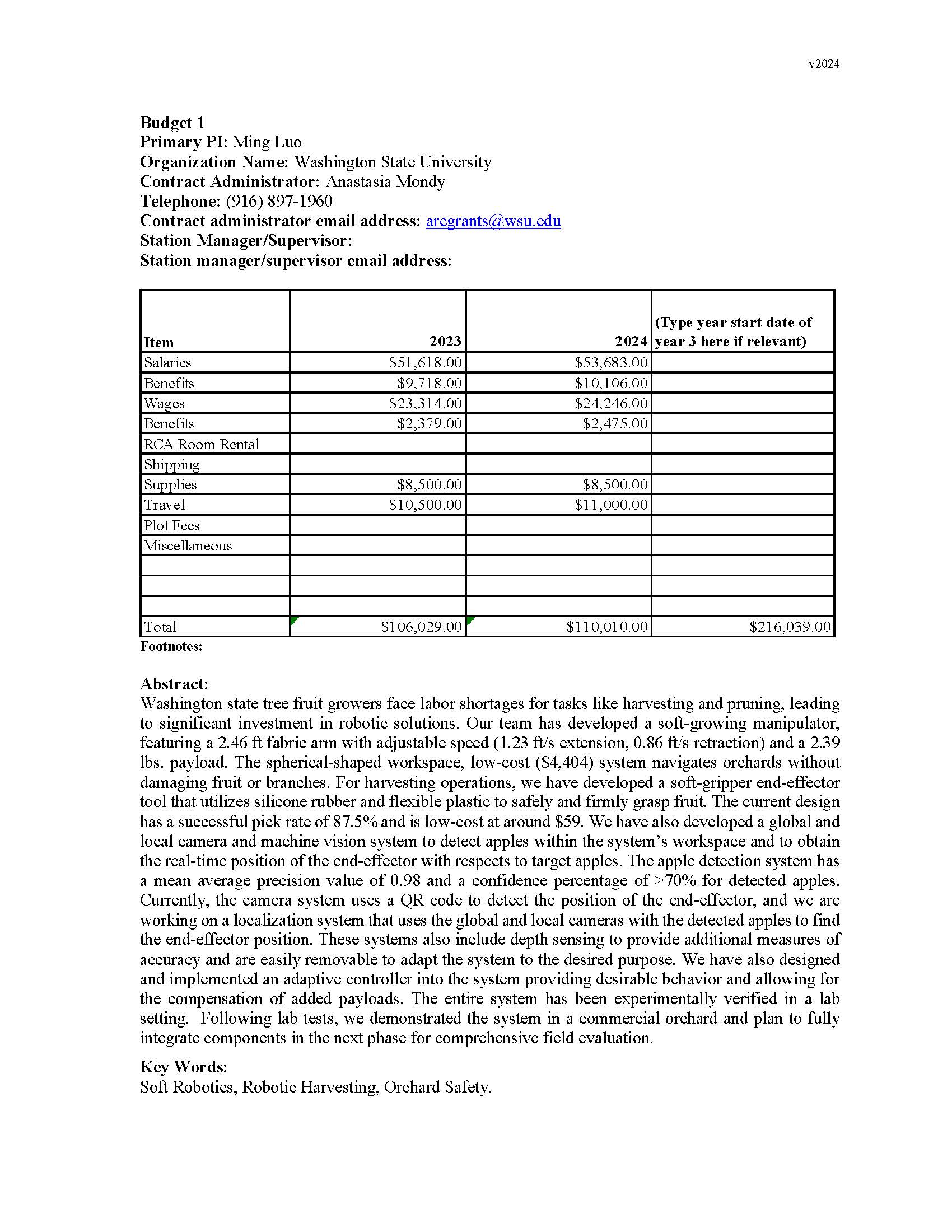

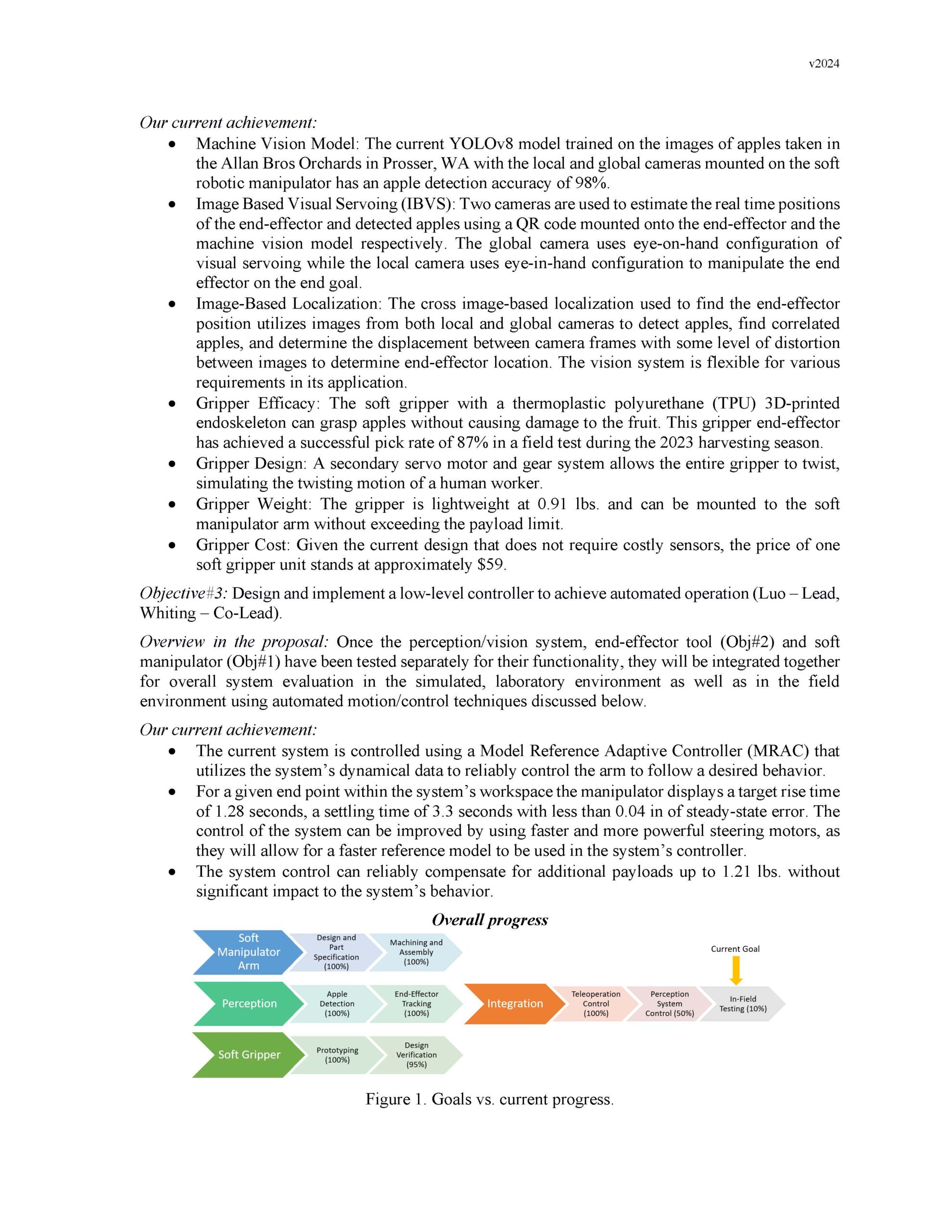

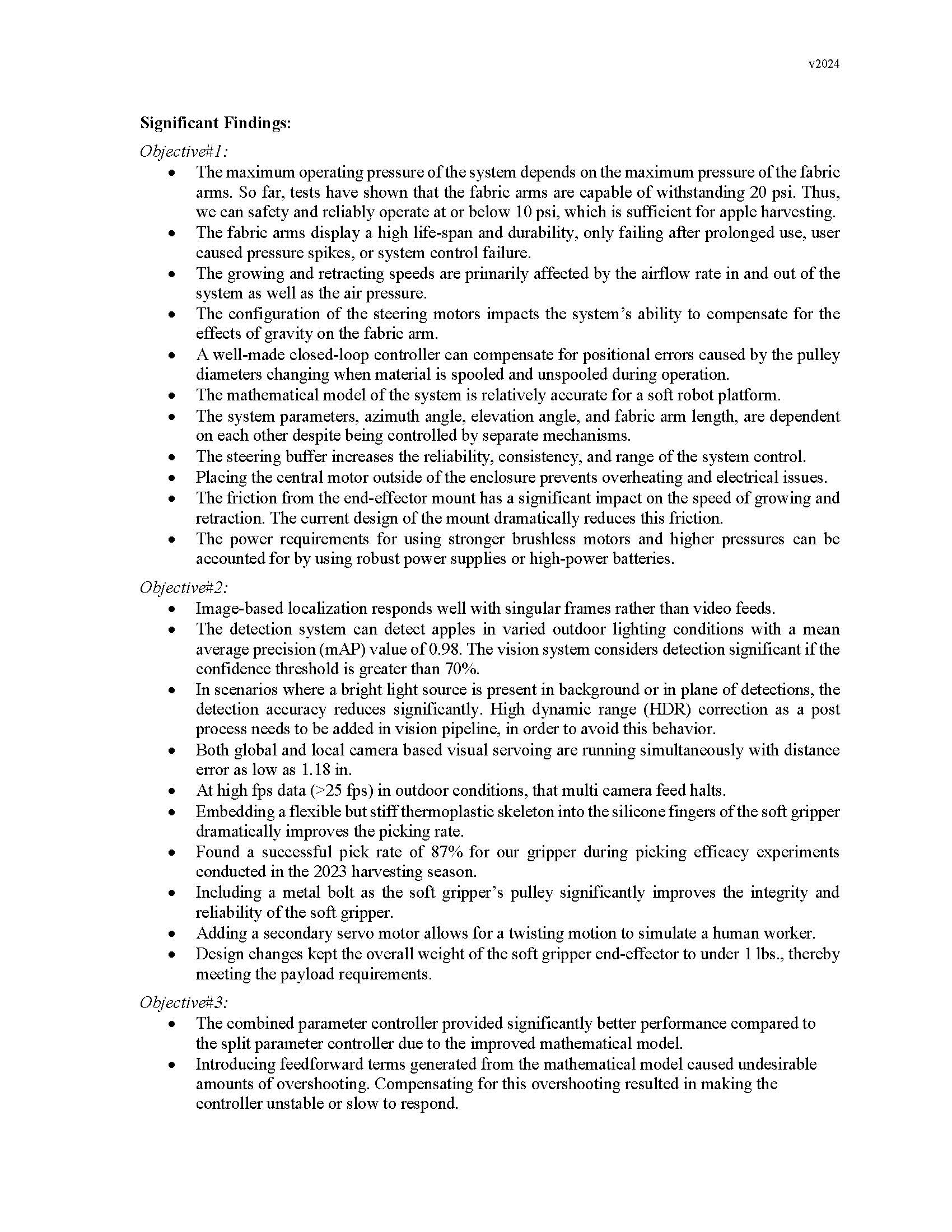

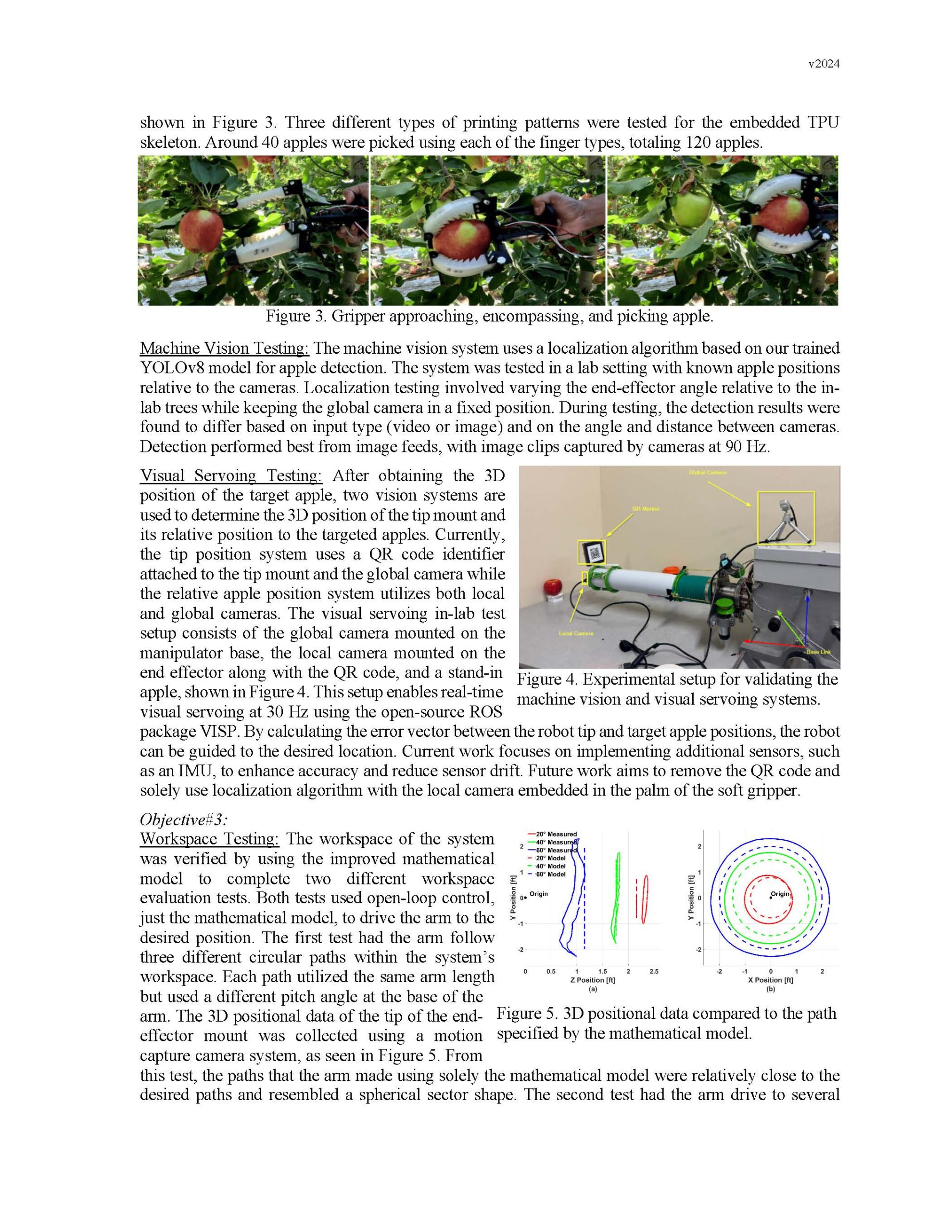

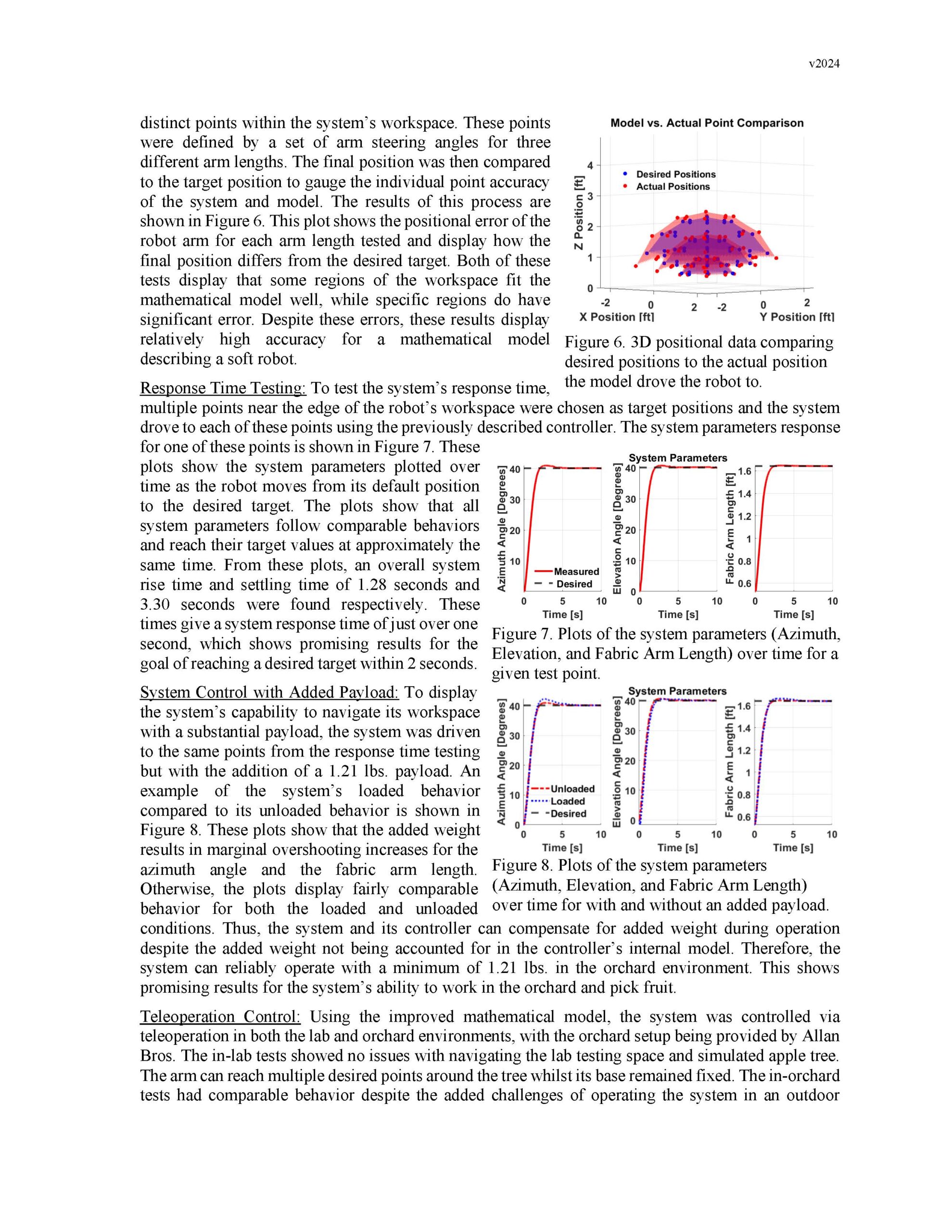

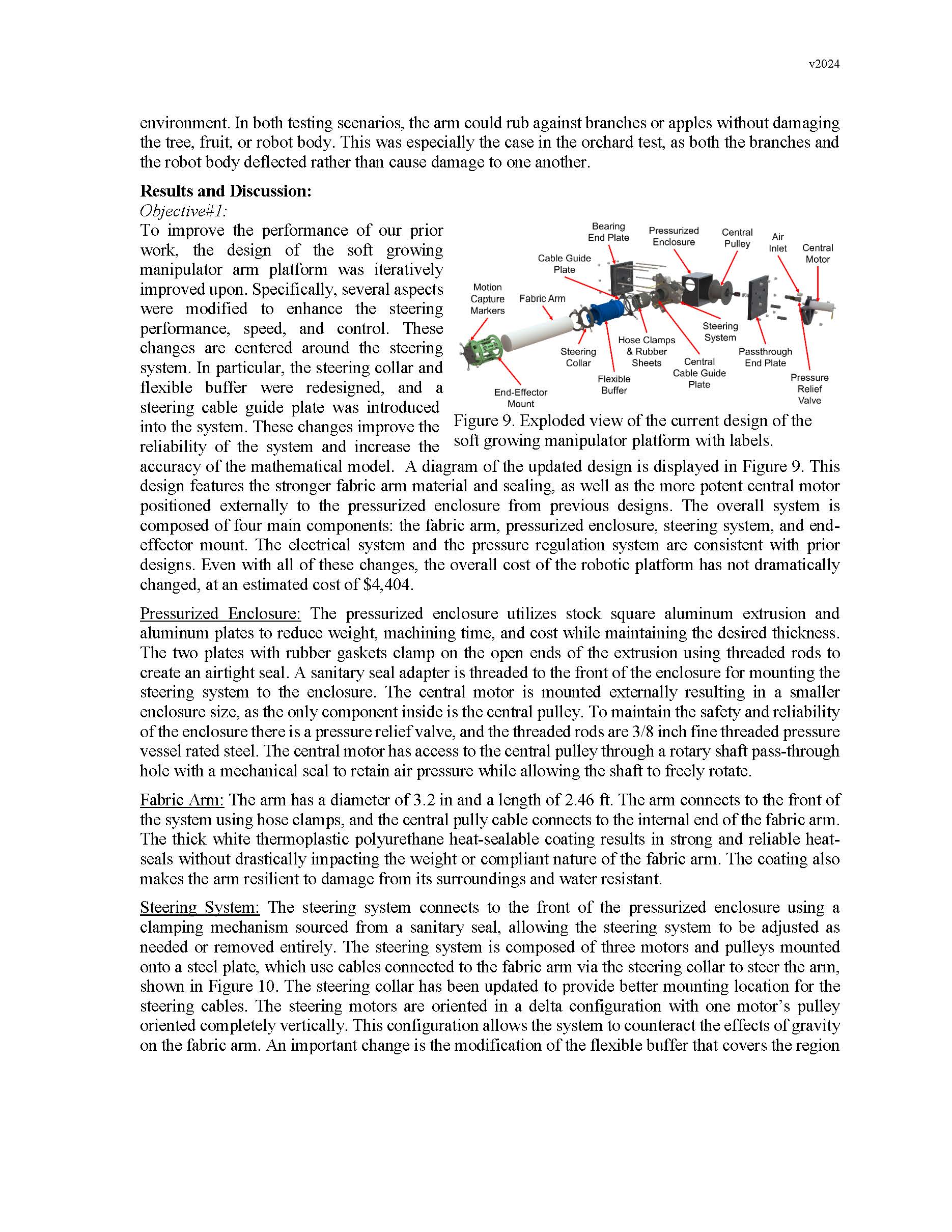

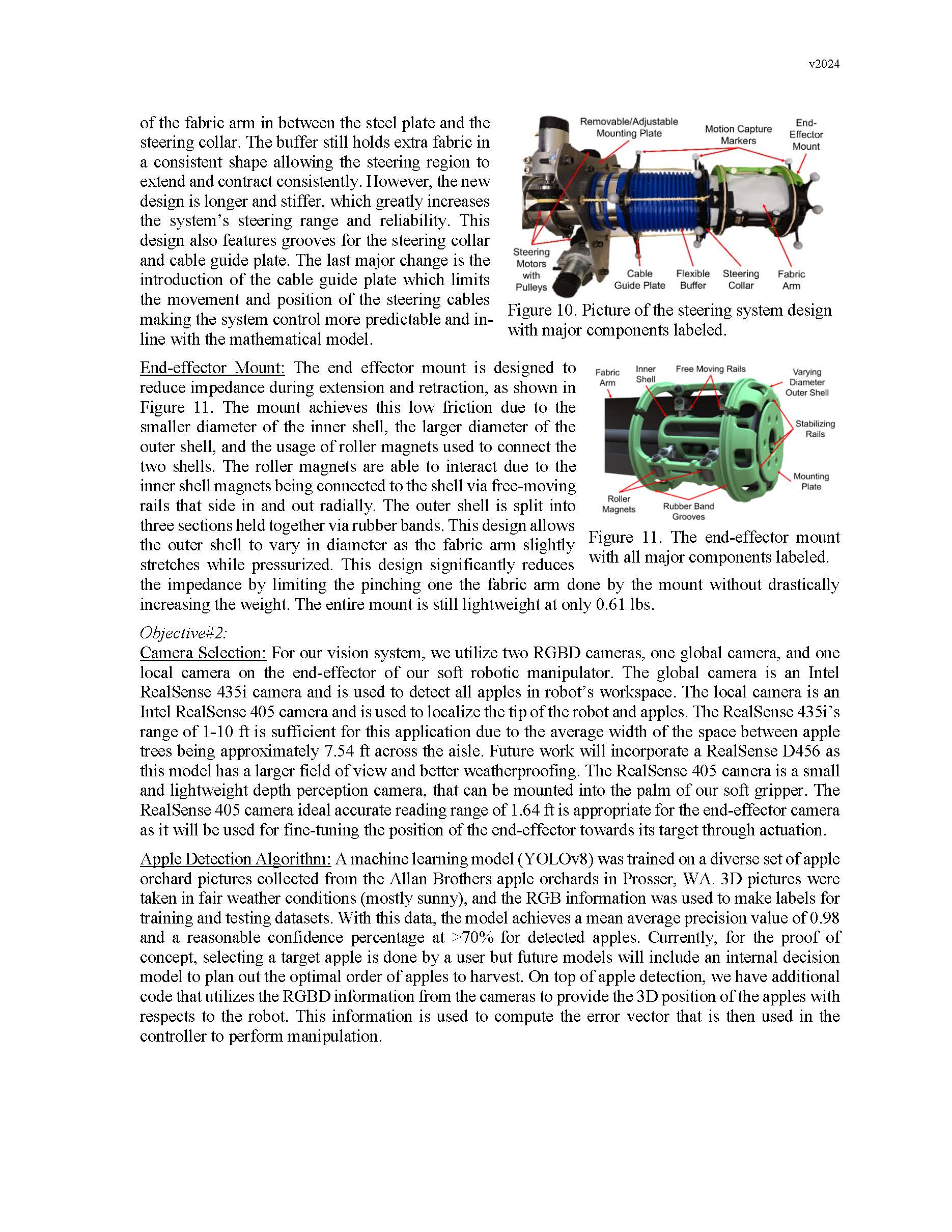

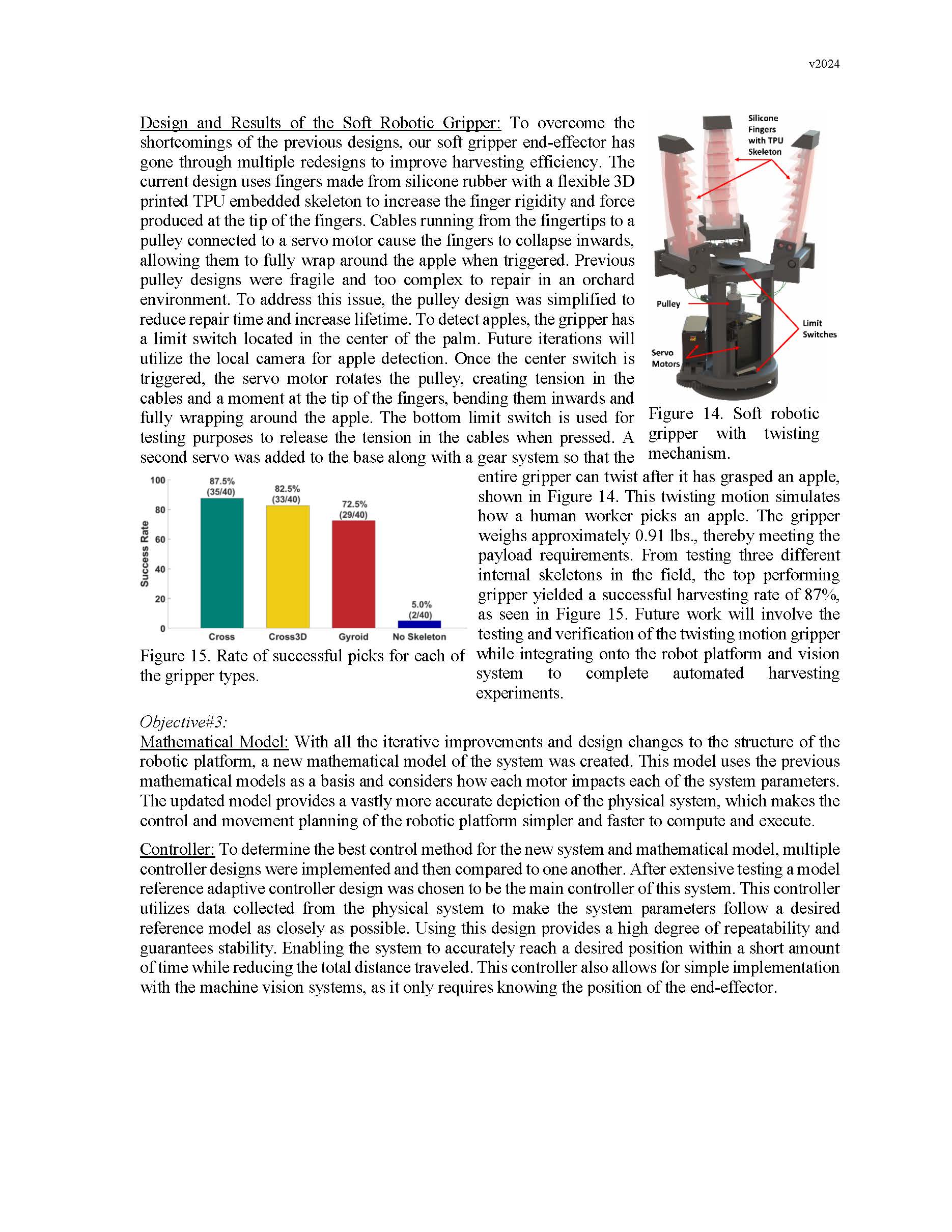

Summary: Washington state tree fruit growers face labor shortages for tasks like harvesting and pruning, leading to significant investment in robotic solutions. Our team has developed a soft-growing manipulator, featuring a 2.46 ft fabric arm with adjustable speed (1.23 ft/s extension, 0.86 ft/s retraction) and a 2.39 lbs. payload. The spherical-shaped workspace, low-cost ($4,404) system navigates orchards without damaging fruit or branches. For harvesting operations, we have developed a soft-gripper end-effector tool that utilizes silicone rubber and flexible plastic to safely and firmly grasp fruit. The current design has a successful pick rate of 87.5% and is low-cost at around $59. We have also developed a global and local camera and machine vision system to detect apples within the system’s workspace and to obtain the real-time position of the end-effector with respects to target apples. The apple detection system has a mean average precision value of 0.98 and a confidence percentage of >70% for detected apples. Currently, the camera system uses a QR code to detect the position of the end-effector, and we are working on a localization system that uses the global and local cameras with the detected apples to find the end-effector position. These systems also include depth sensing to provide additional measures of accuracy and are easily removable to adapt the system to the desired purpose. We have also designed and implemented an adaptive controller into the system providing desirable behavior and allowing for the compensation of added payloads. The entire system has been experimentally verified in a lab setting. Following lab tests, we demonstrated the system in a commercial orchard and plan to fully integrate components in the next phase for comprehensive field evaluation.

Keywords: