Automated Apple Harvester

Author: Marc Grossman

Published: 2025

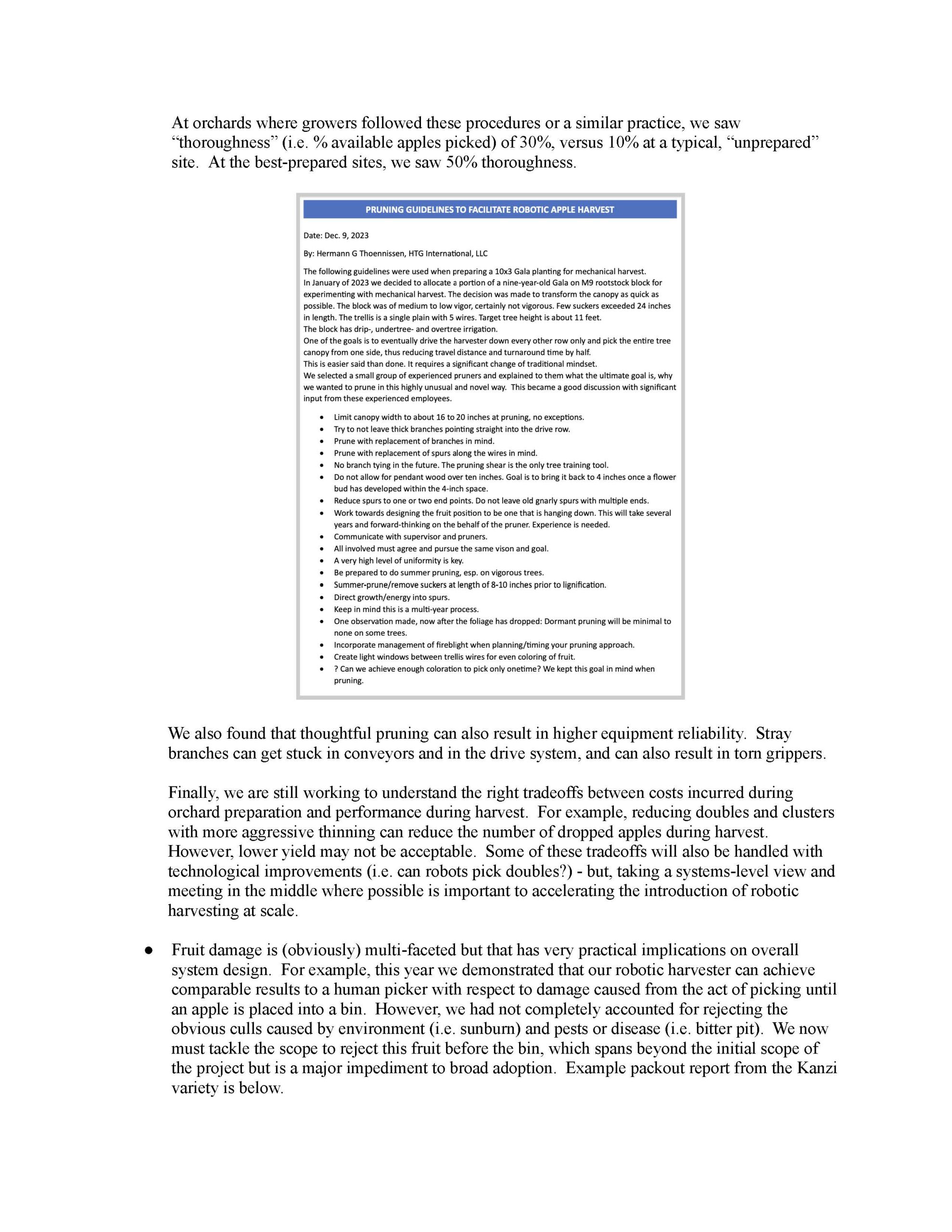

Summary: Washington apple growers face pressures from labor supply and cost, especially during harvest. This pressure will likely continue to worsen, as wages are expected to double (again) in the next decade. This project explores a new “robot-first” reality in which robots lead during harvest, picking 30% or more of ripe fruit as they pass, with a smaller human picker crew following behind. To make robotic harvest reliably cost competitive, several technological discoveries and advances are necessary. For example, robotic arms need to be affordable, reliable and flexible. Grippers need to be designed to handle fruit gently while also causing minimal damage to the tree. Once picked, apples need to be placed gently into a standard industry bin. All of this needs to be done to a near-human standard for color picking, and without disruption to typical harvest operations. Over the course of three seasons from 2022-2024, Advanced Farm Technologies developed prototype robotic apple harvesters that achieved many of these goals. These efforts have made robotic apple harvest within reach, and have also significantly advanced the overall state of the art in robotics and farm equipment.

Keywords: