Automated picking hand development

Author: Tony Koselka, Derek Morikawa

Published: 2007

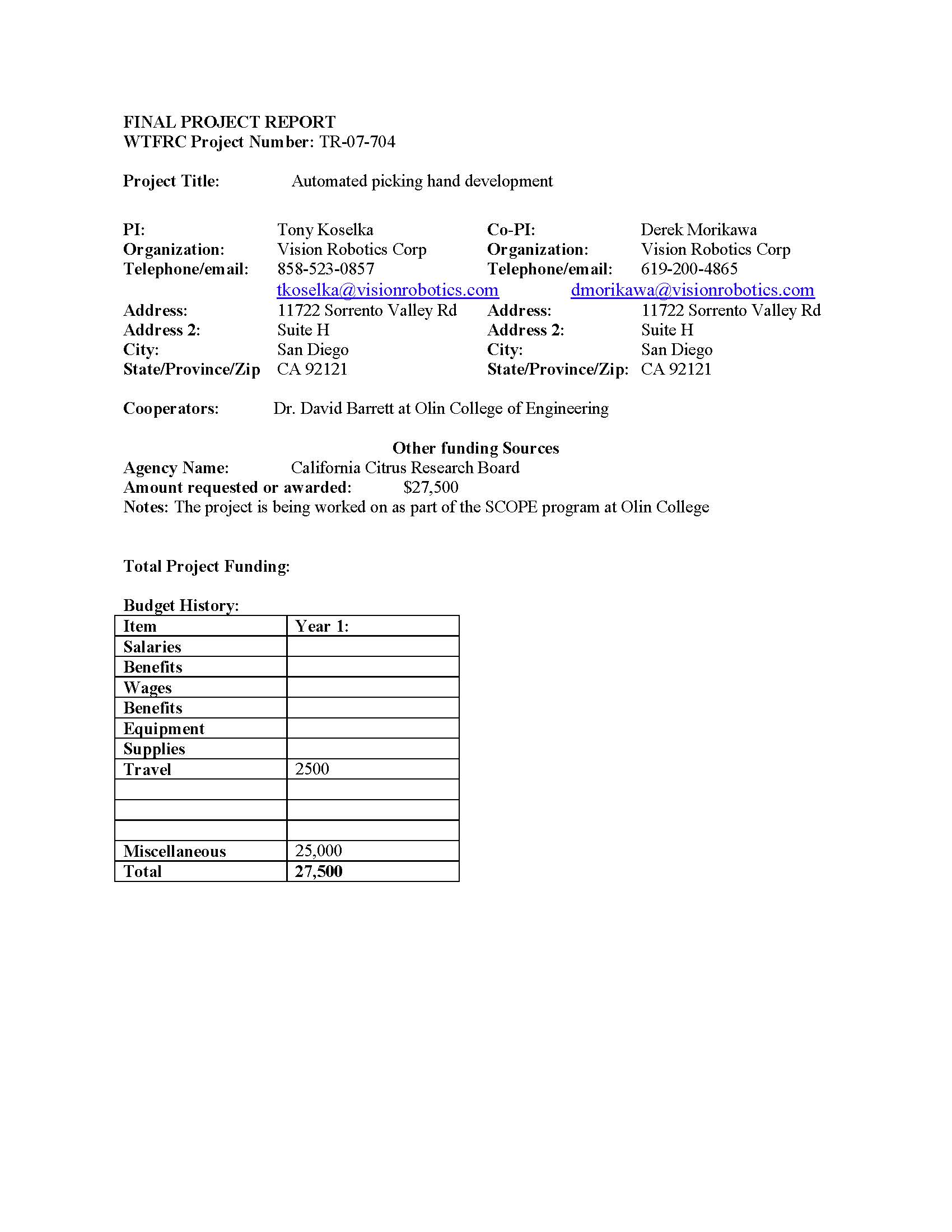

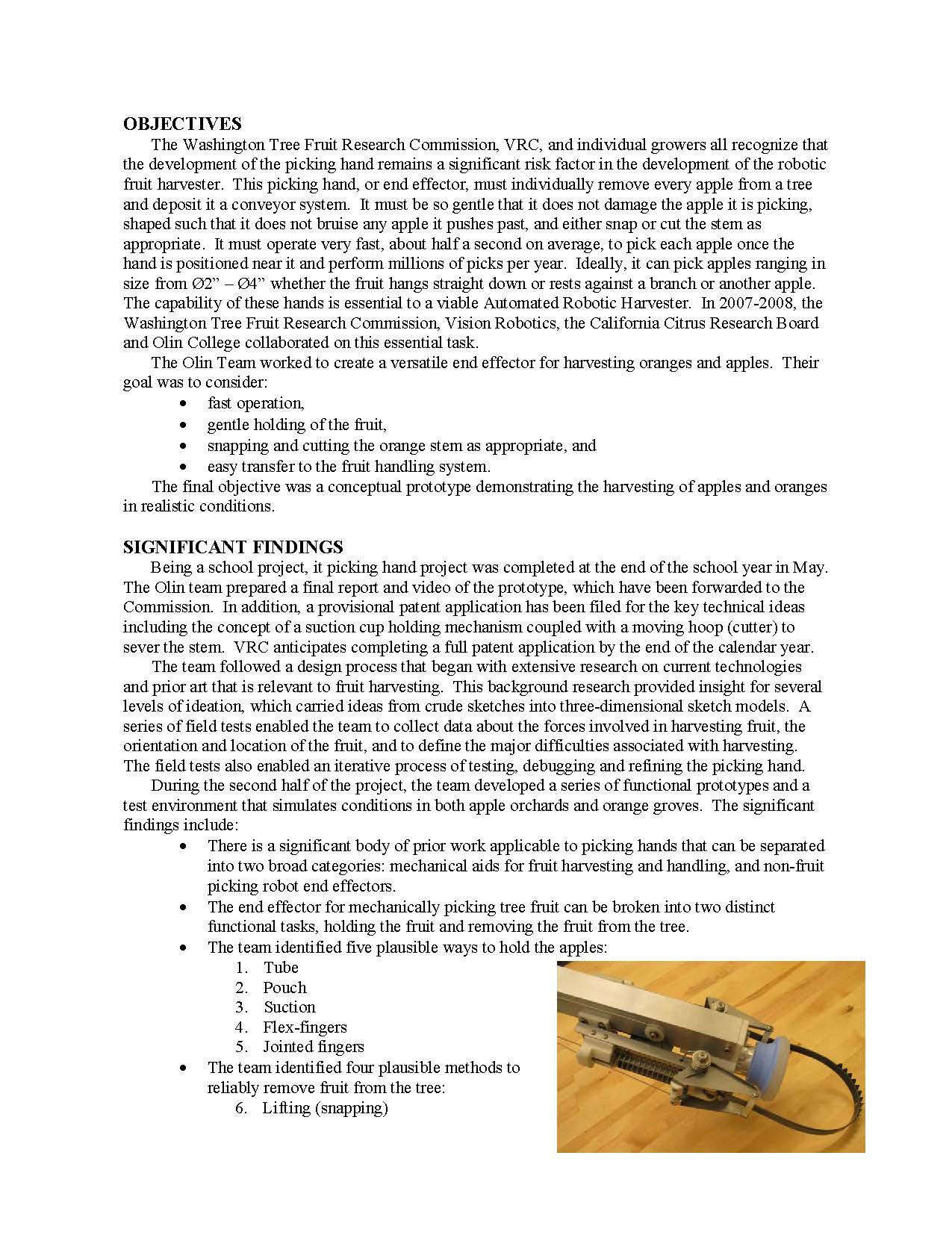

Summary: The Washington Tree Fruit Research Commission, VRC, and individual growers all recognize that the development of the picking hand remains a significant risk factor in the development of the robotic fruit harvester. This picking hand, or end effector, must individually remove every apple from a tree and deposit it a conveyor system. It must be so gentle that it does not damage the apple it is picking, shaped such that it does not bruise any apple it pushes past, and either snap or cut the stem as appropriate. It must operate very fast, about half a second on average, to pick each apple once the hand is positioned near it and perform millions of picks per year. Ideally, it can pick apples ranging in size from Ø2” – Ø4” whether the fruit hangs straight down or rests against a branch or another apple. The capability of these hands is essential to a viable Automated Robotic Harvester. In 2007-2008, the Washington Tree Fruit Research Commission, Vision Robotics, the California Citrus Research Board and Olin College collaborated on this essential task. The Olin Team worked to create a versatile end effector for harvesting oranges and apples. Their goal was to consider: • fast operation, • gentle holding of the fruit, • snapping and cutting the orange stem as appropriate, and • easy transfer to the fruit handling system. The final objective was a conceptual prototype demonstrating the harvesting of apples and oranges in realistic conditions.

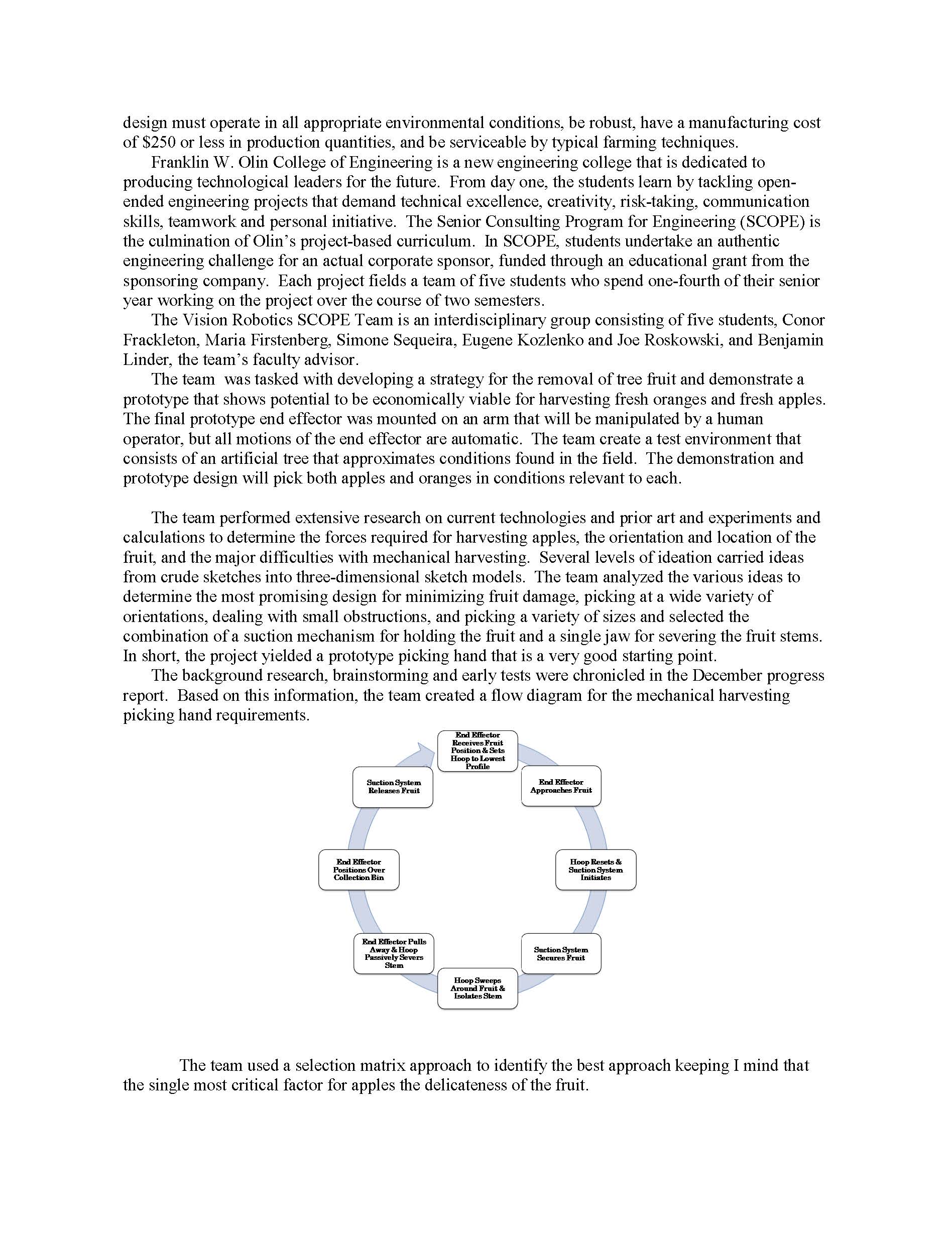

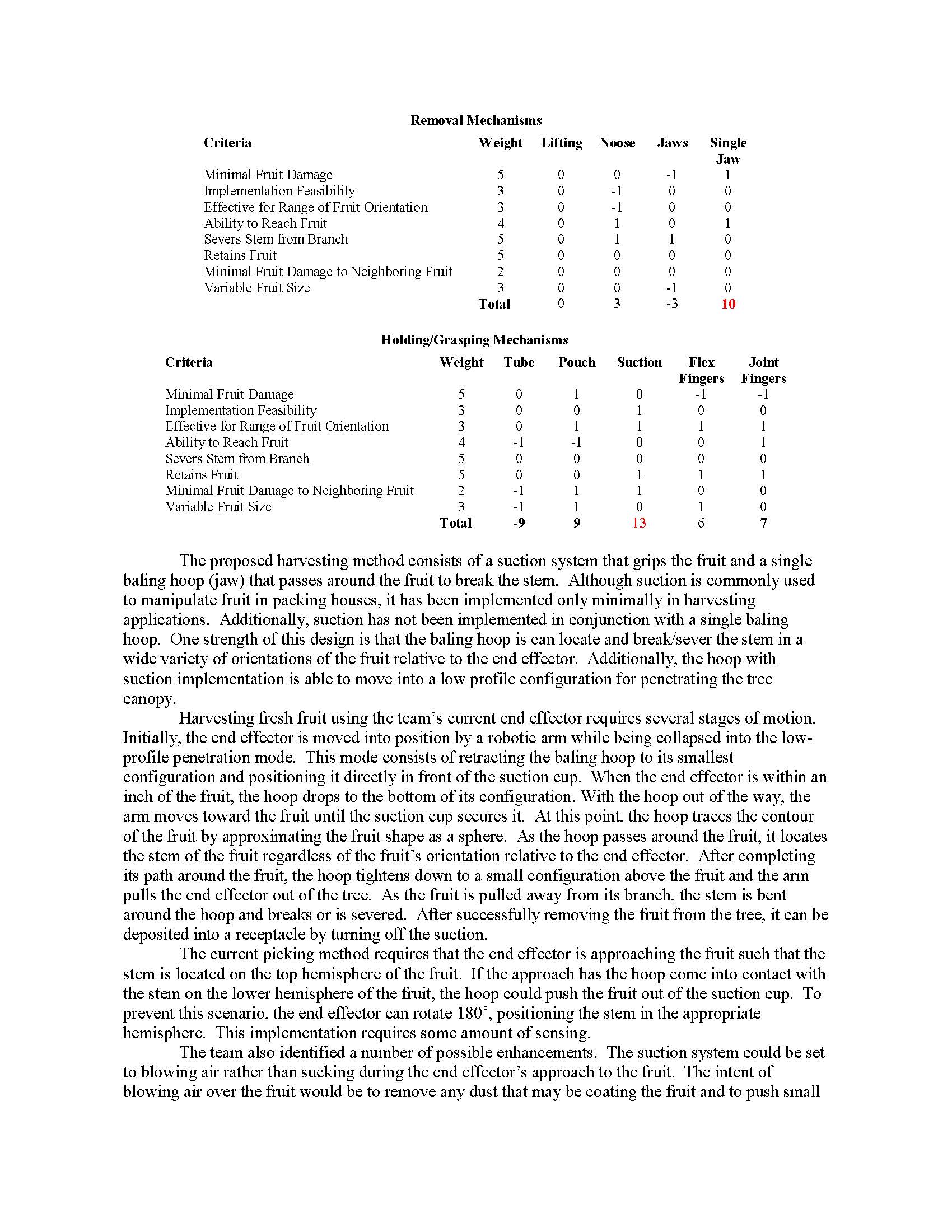

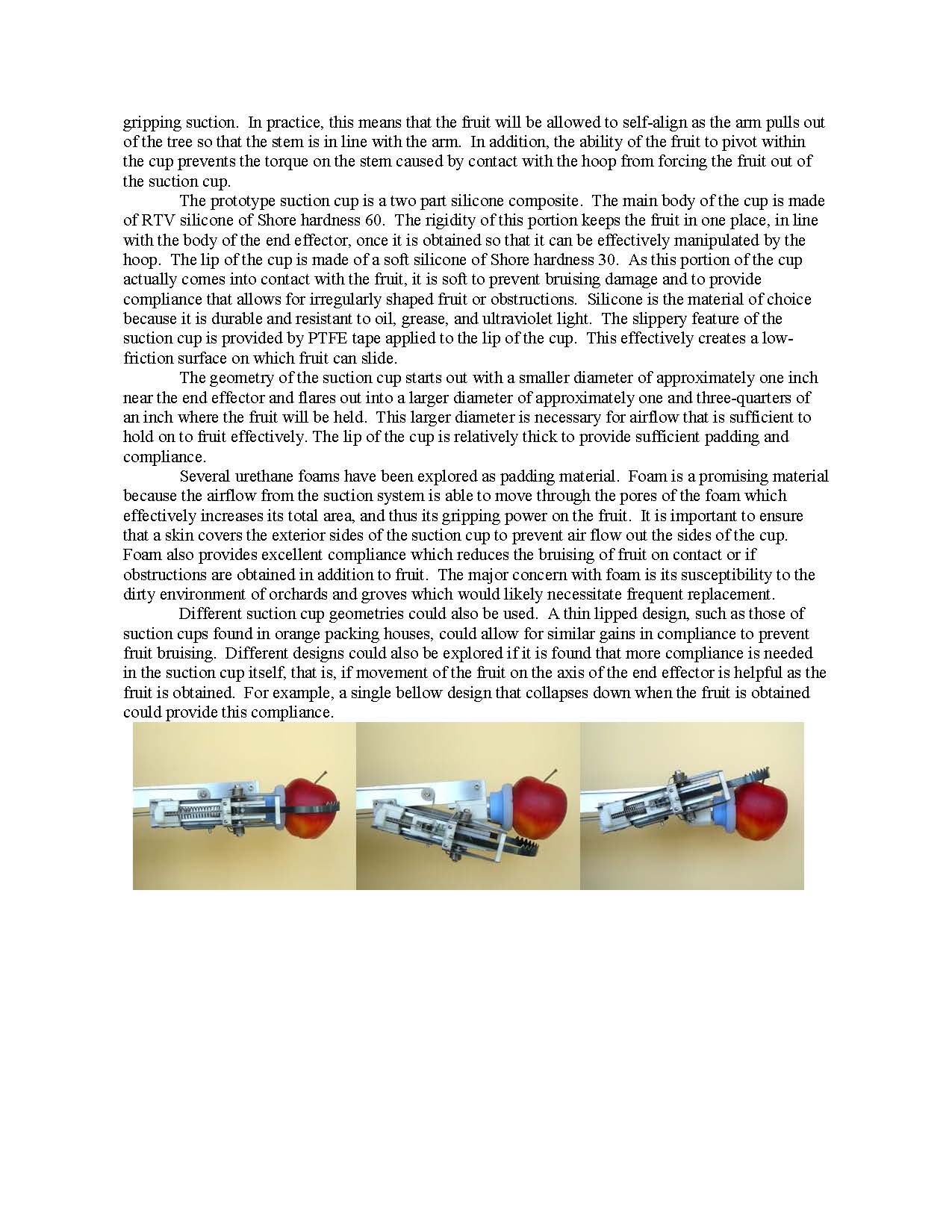

Keywords: