Mechanization Research

Author: Nagarajan Ramalingam

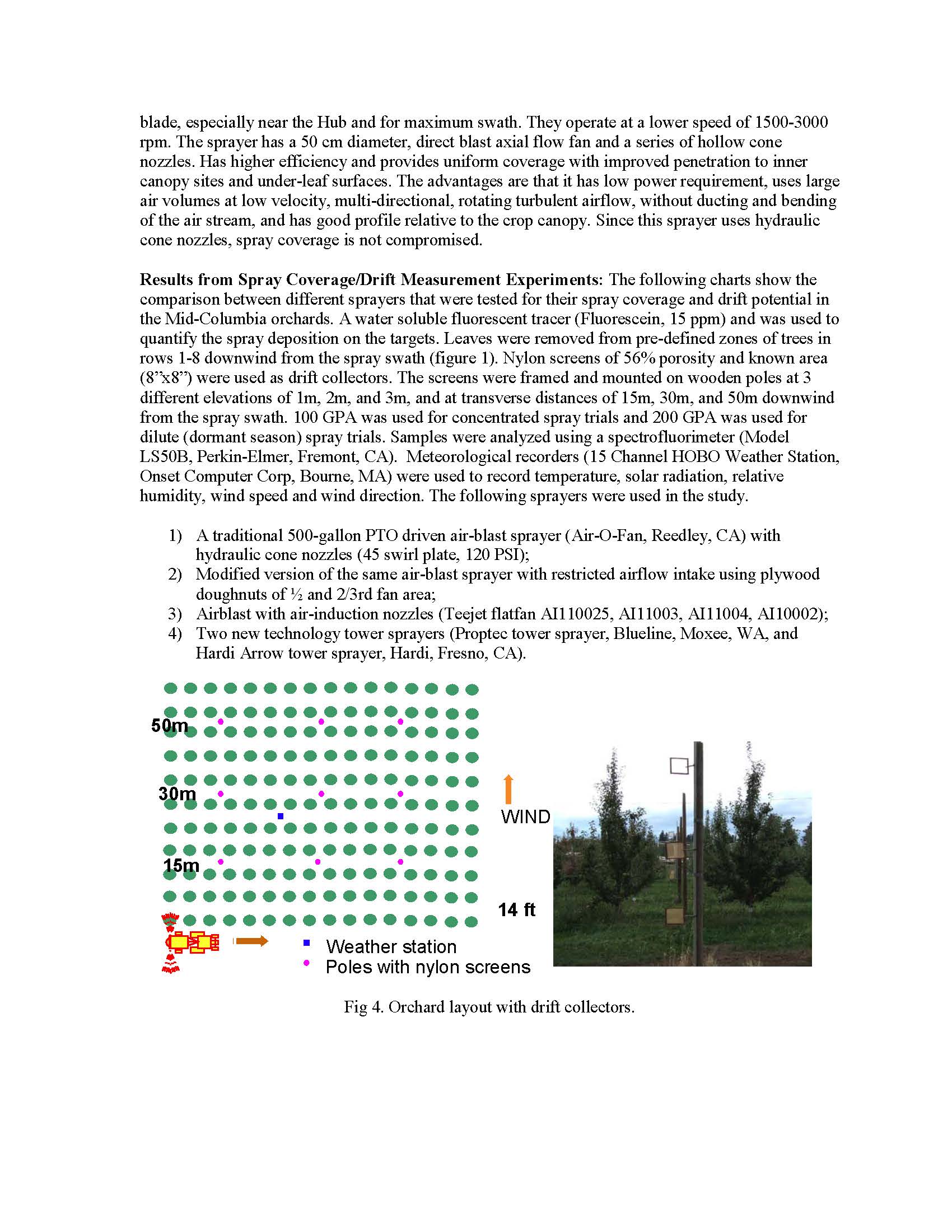

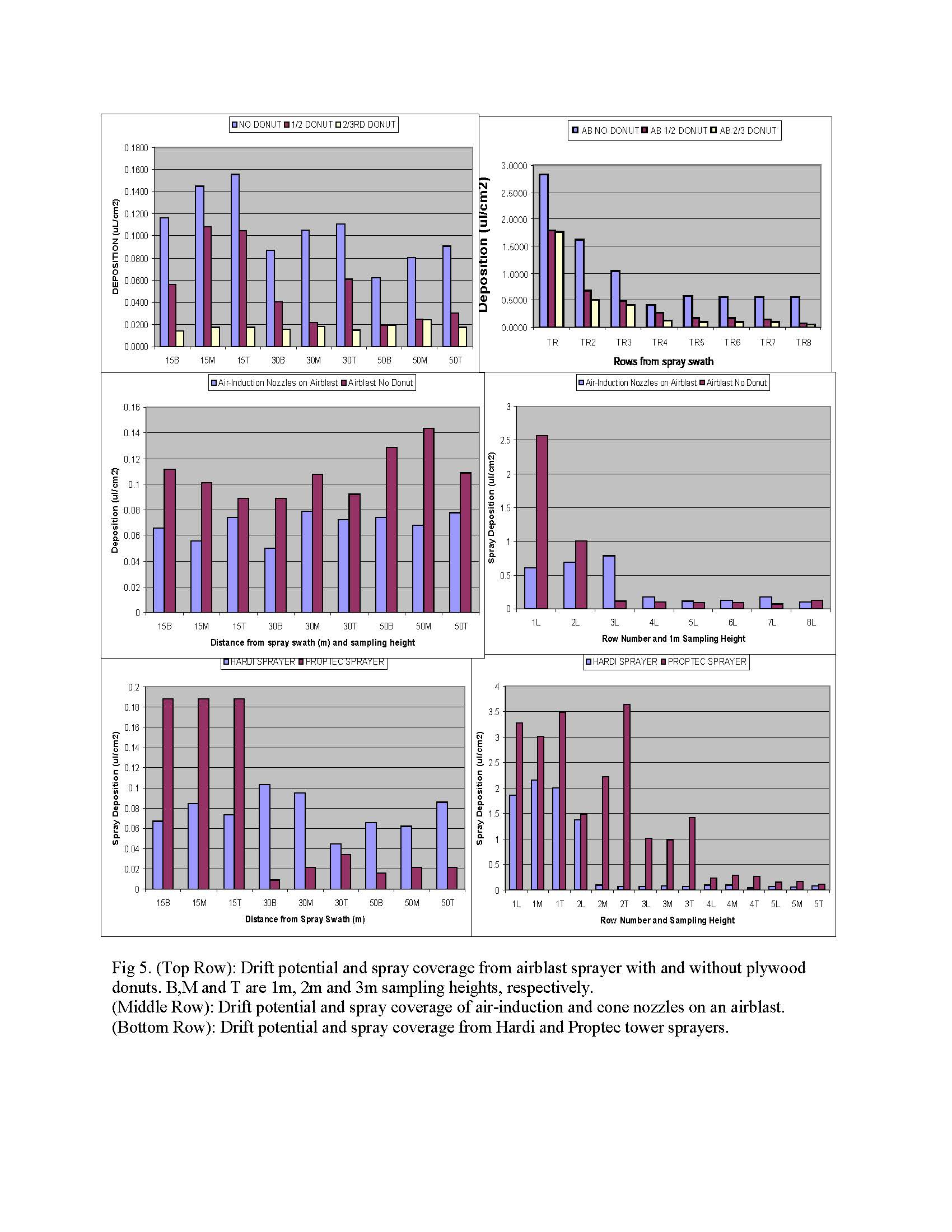

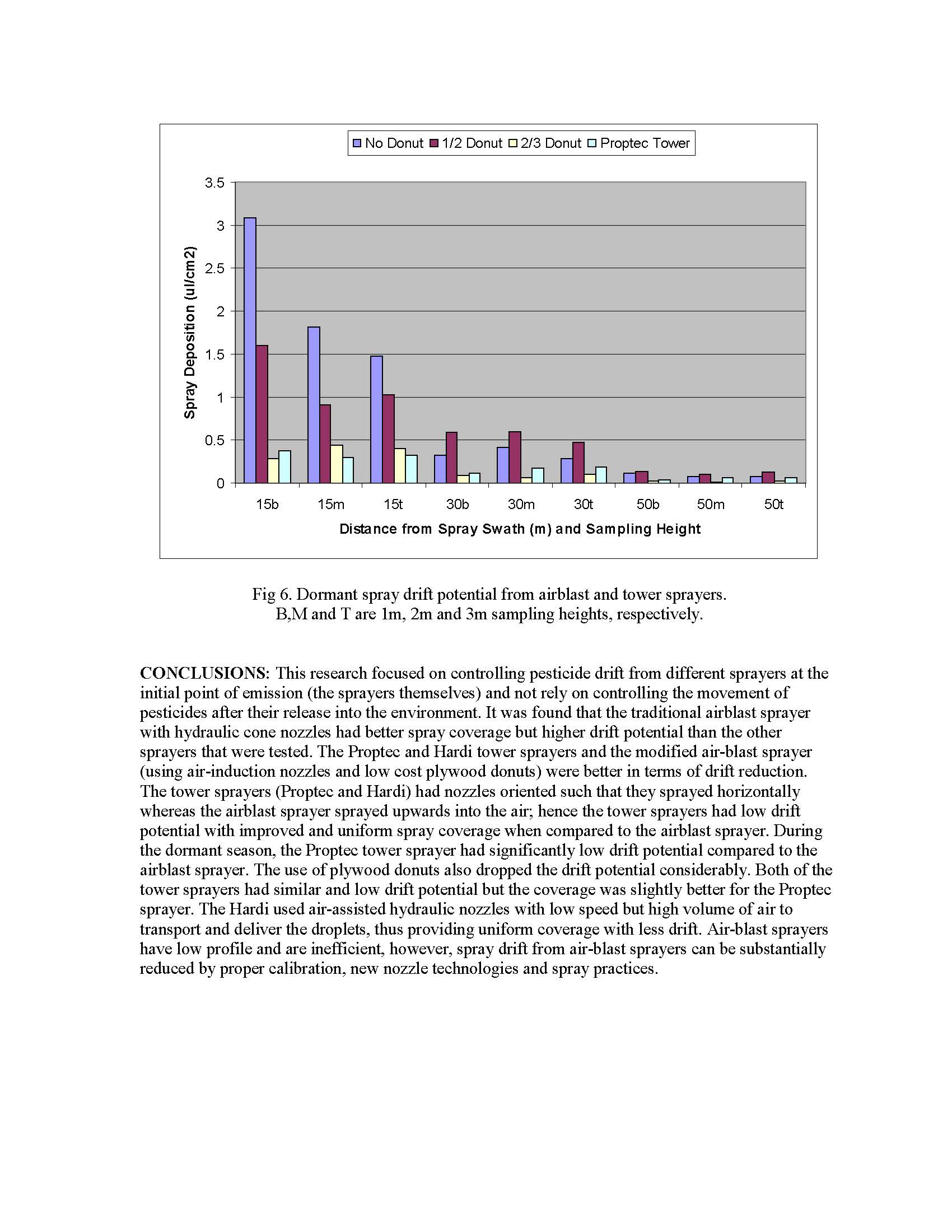

Summary: This research focused on controlling pesticide drift from different sprayers at the initial point of emission (the sprayers themselves) and not rely on controlling the movement of pesticides after their release into the environment. It was found that the traditional airblast sprayer with hydraulic cone nozzles had better spray coverage but higher drift potential than the other sprayers that were tested. The Proptec and Hardi tower sprayers and the modified air-blast sprayer (using air-induction nozzles and low cost plywood donuts) were better in terms of drift reduction. The tower sprayers (Proptec and Hardi) had nozzles oriented such that they sprayed horizontally whereas the airblast sprayer sprayed upwards into the air; hence the tower sprayers had low drift potential with improved and uniform spray coverage when compared to the airblast sprayer. During the dormant season, the Proptec tower sprayer had significantly low drift potential compared to the airblast sprayer. The use of plywood donuts also dropped the drift potential considerably. Both of the tower sprayers had similar and low drift potential but the coverage was slightly better for the Proptec sprayer. The Hardi used air-assisted hydraulic nozzles with low speed but high volume of air to transport and deliver the droplets, thus providing uniform coverage with less drift. Air-blast sprayers have low profile and are inefficient, however, spray drift from air-blast sprayers can be substantially reduced by proper calibration, new nozzle technologies and spray practices.

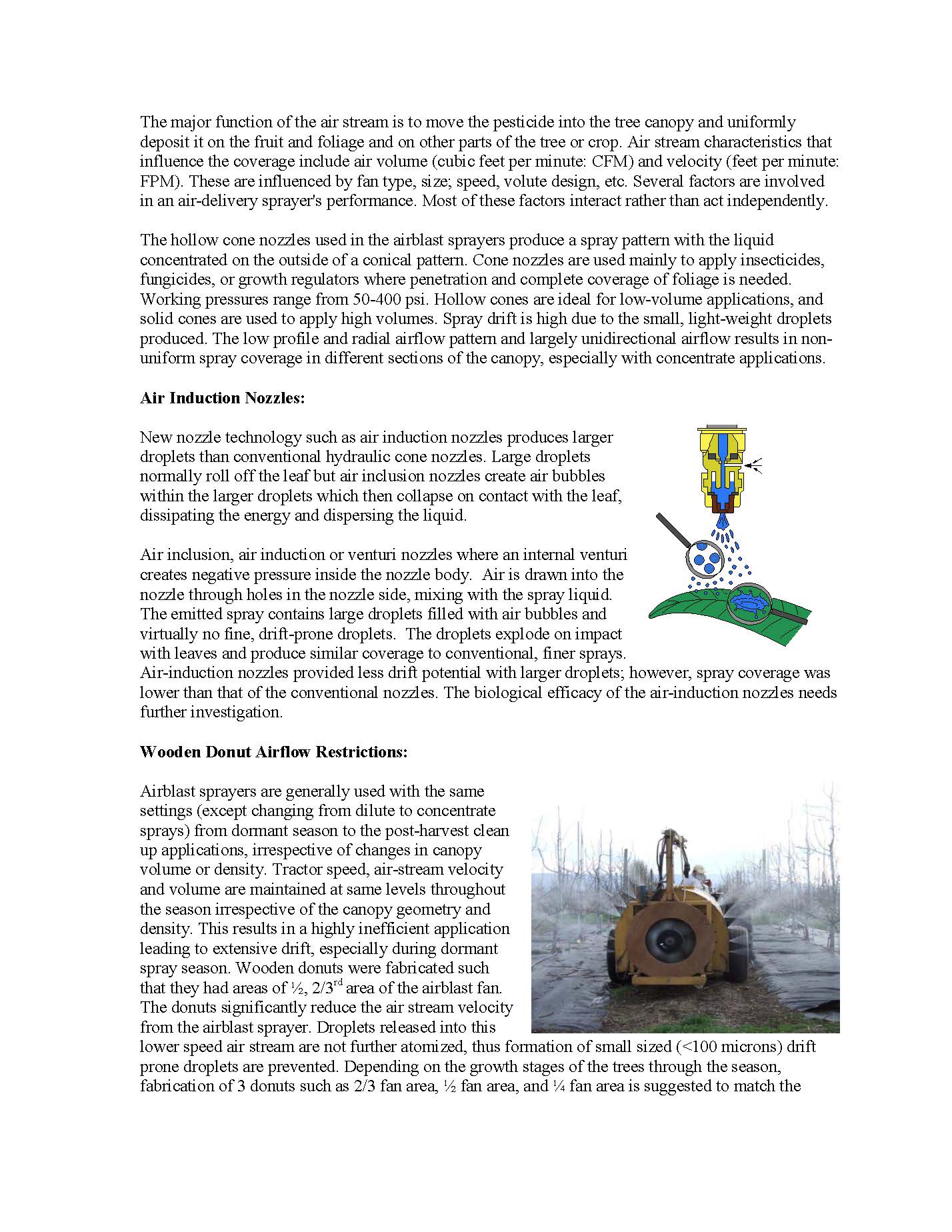

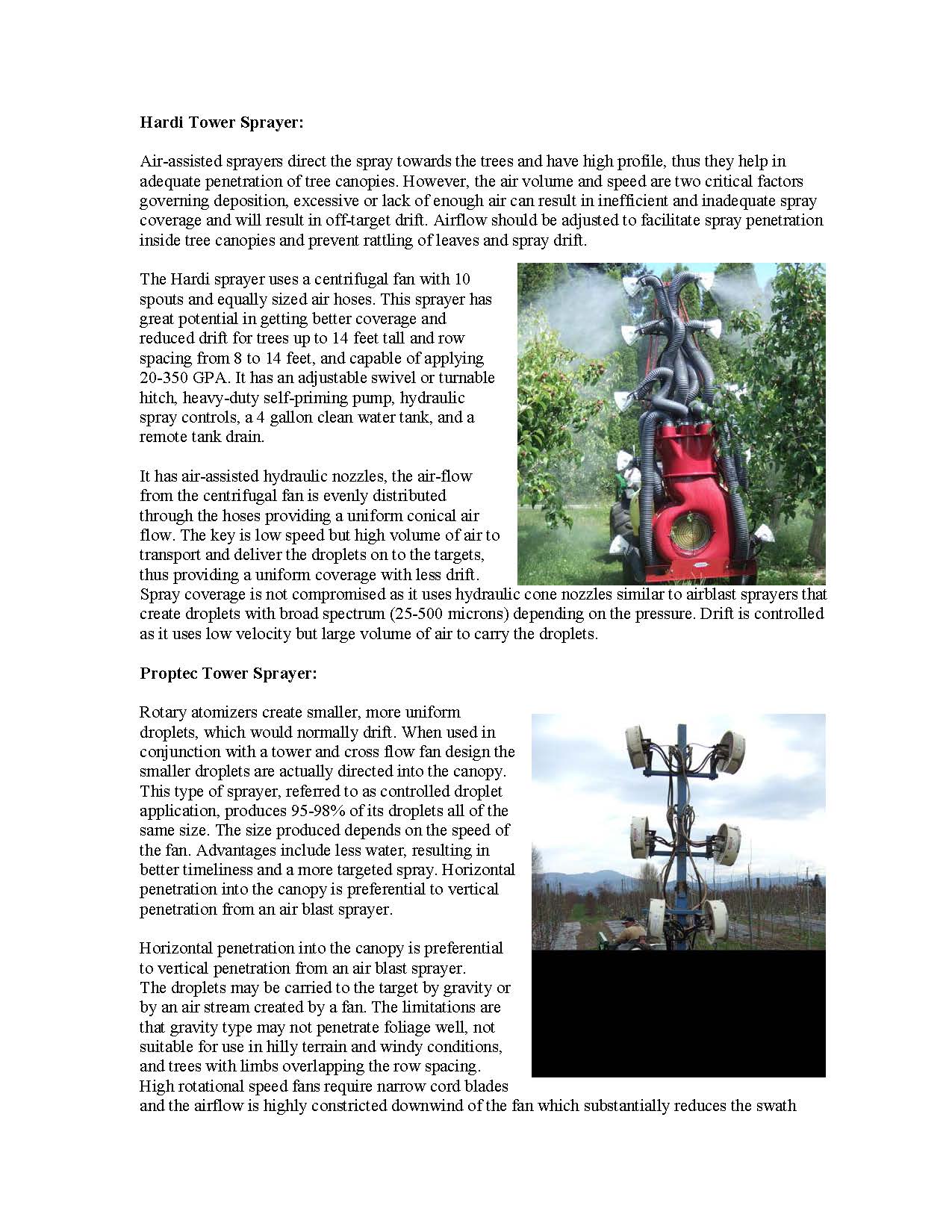

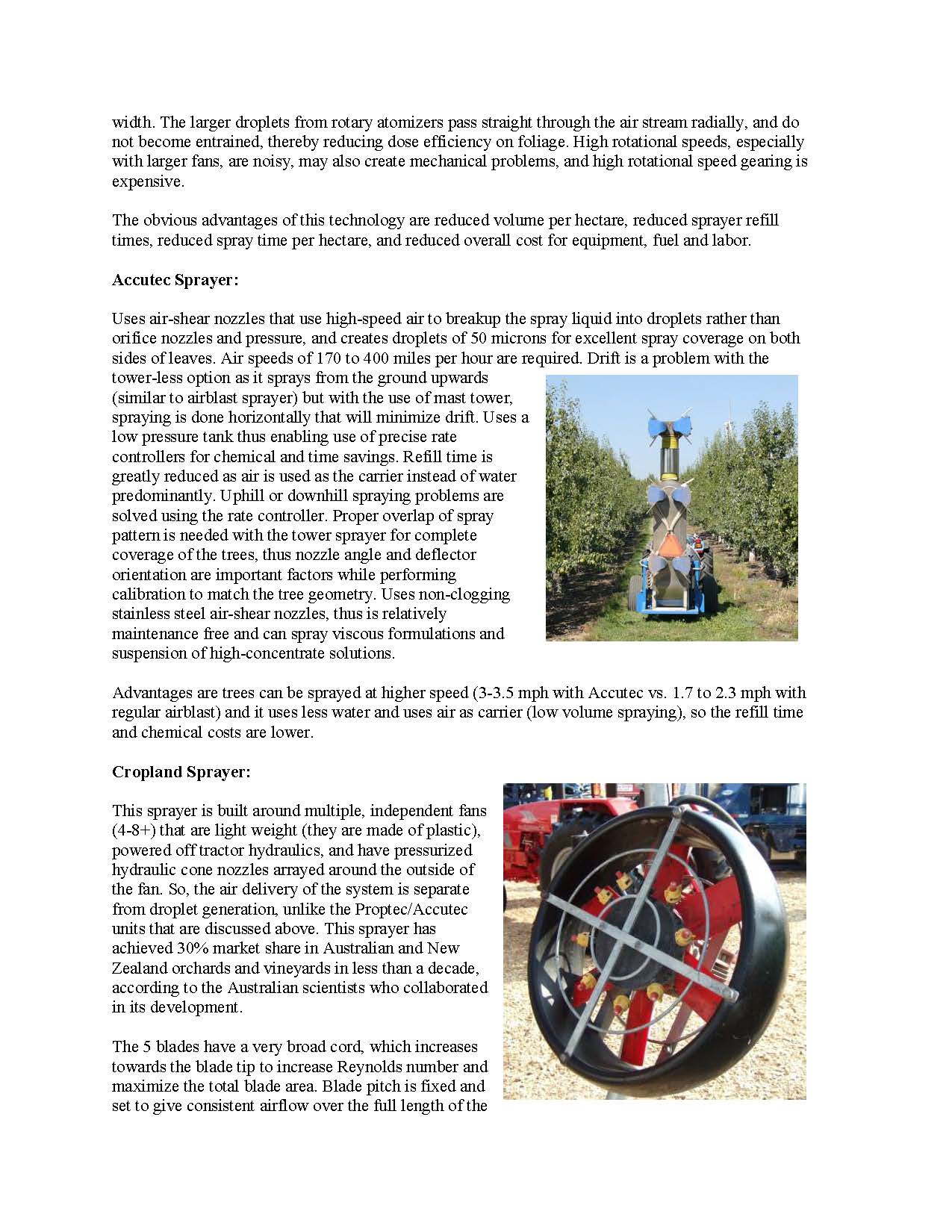

Keywords: